Cable ties

Self locking plastic cable ties available in a wide range of colours and sizes

REQUEST FOR QUOTATION

Description

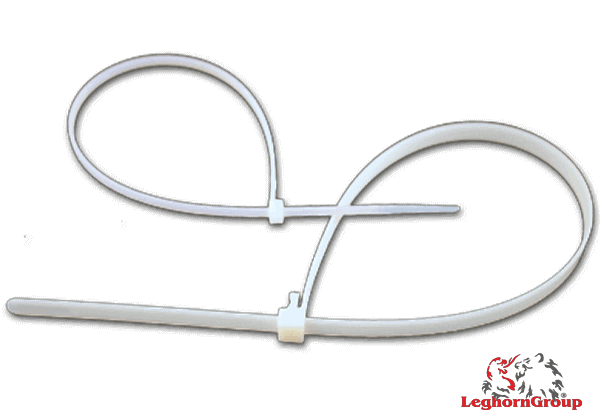

Cable ties

Self locking cable ties are generally designed to fasten cable bundles, but they can be also used for hundreds of other needs. Their locking system is very simple: on the one hand there is a head with a self-locking closing system and along the entire tail of the band there is a series of teeth that will fit into the head. They are mainly used for indoor use and offer high tensile strength with low insertion force. Thanks to our forty years of experience, our self-locking cable ties have gained the loyalty of our customers.

Examples of use

Examples of use

These cable ties are used in different field of application, e.g. electric installations, in large quantities for festivals and summer events to group the cables that have been laid out, in the telecommunications sector to manage network cables and in the construction industry to fix protective tarps.

Customisation

Customisation

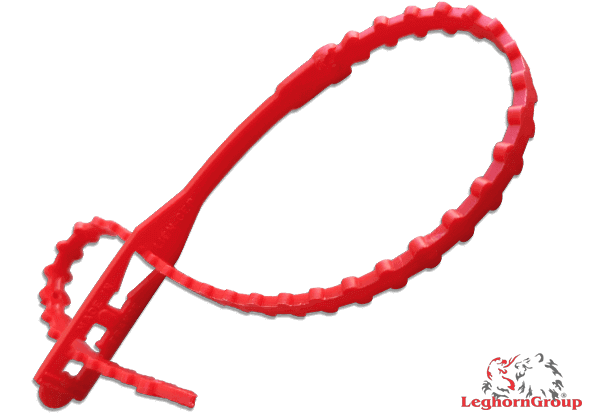

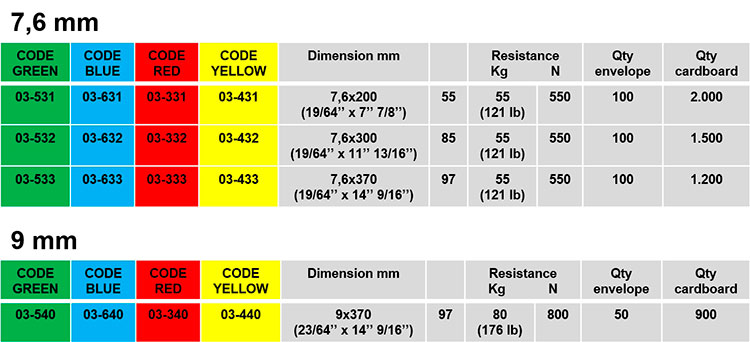

Our cable ties are available in a wide range colours in order to blend into different environments. They are the ideal solution for closing hospital waste bags if customized. In fact by matching a colour with a writing, there will be an immediate control of the bag.

Relevance

Relevance

It is significantly important to immediately track and identify cables ties is some particular field of application.

Cable ties with customization and numbering may speed up work procedures by improving security.

This system allows the quick and easy identification of some cable ties, e.g. if a RED cable ties has the writing “LIVE” printed on it, it may have a crucial importance and it can be directly noticed.

Another interesting printing solution is to mark cable ties with the same progressive numbering to easily track a trial of cables.

How to choose the right cable tie

How to choose the right cable tie

The most important characteristics of a cable tie are:

a. The raw-material it is made of , depending also on its application

b. The tensile strength it can stand

c. The min and max diameter it can bundle

d. The flammability rating

e. The shape of the tie in case of particular applications

Chemical agents such as dusts, liquids and gases can damage cable tie’s material. In fact, if cable ties come into contact with several compounds, its physical and mechanical properties may be altered. In this case, the performance of the product may not reach the standard declared values.

All polymers including the polyamides used for the production of cable ties are sensitive to UV radiation. The most common additive used for protecting polyamides from UV radiation is carbon powder commonly known as “carbon black”.

Natural cable ties have low resistance to UV radiation and therefore are not suggested for outdoor applications. Black cable ties are additivated with carbon black. They have improved weather and UV radiation resistance and are more suitable for outdoor applications, comparing to the natural one. Tests performed in laboratories give for black cable ties a resistance till 150 hours QUV-B radiation following ISO 4892 norm. This can be compared to ca. 3 years outdoor resistance on average exposure to South-European areas.

Temperature resistance

Temperature resistance

All polymers including also polyamides used for the production of cable ties are sensitive to low temperatures; application of polyamide 6.6 cable ties is possible till around -10°C. Standard polyamide becomes very brittle at temperatures below -40°C (min suggested service temperature for continuous use).

(in case of lower temperatures, cable ties become really brittle)

Tear resistance

Tear resistance

LeghornGroup’ cable ties are tested following the main international standards CEI EN 62275.

The standard testing conditions are 23°C and 50% of relative humidity.

It is important to underline that the values arising from those laboratory tests are indicatives and they refer to the above-mentioned conditions.

Certificates and approvals

Certificates and approvals

| EN (CENELEC 50146) | 31-10-2005 |

| EN 62275:2015 | 20-01-2017 |

| RoHsDate | 19-05-2015 |

| Halogen – Free | 19-05-2015 |

| DIN CERTCO | 05-09-2005 |

| C E | 30-07-2005 |

| ISO 9001-2015 | 14-09-2018 |

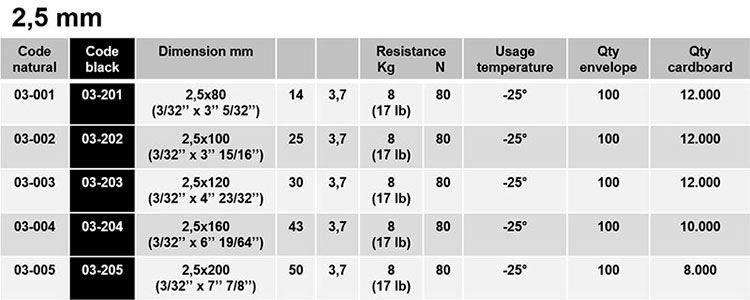

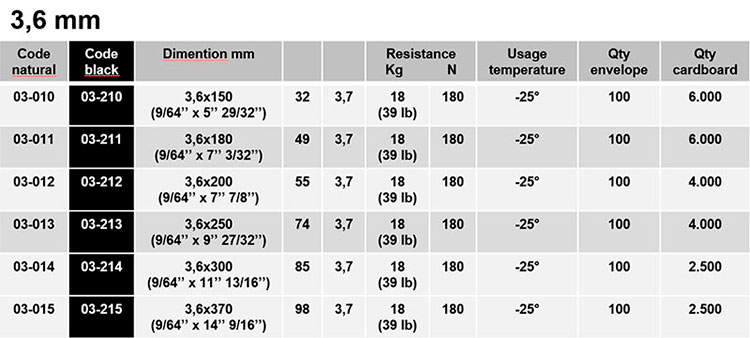

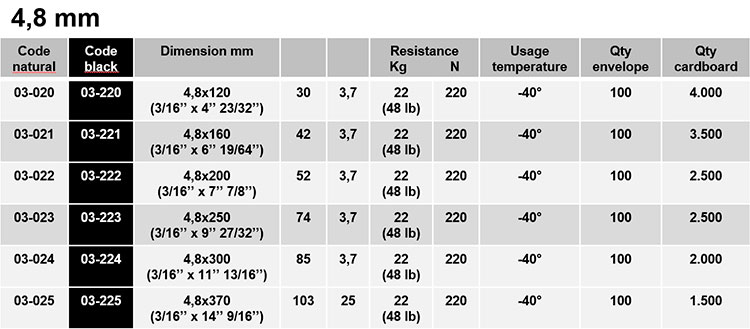

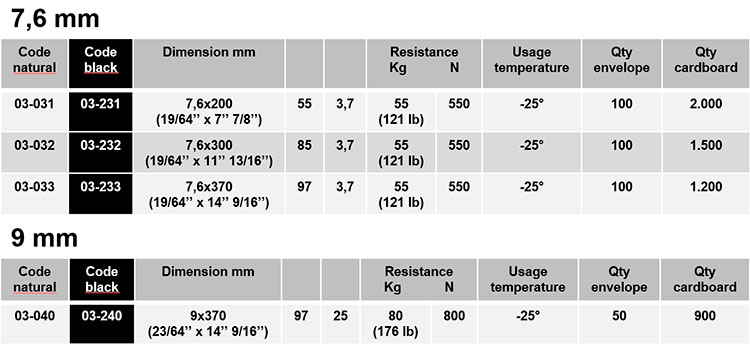

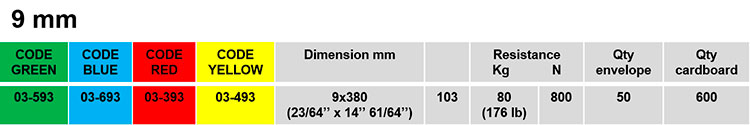

Technical specifications

| Material | Polyamide PA-6.6 |

| Colour | White or black |

| Working temperature | -25° & -40° C up to +85° C |

| Tightening temperature | -10° C up to +60° C |

| Melting point | +260° C |

| Flammability rating | V2 acc- a UL 94 |

| Resistance to chemicals products | High resistance to bases, oils, greases, oil derivatives. Limited resistance to acids. Not resistant to phenols and to chloride solvents |

| Natural cable ties (white colour) of LeghornGroup have low resistance to UV radiation and therefore are not suggested for outdoor applications. | |

| Black cable ties of LeghornGroup are additivated with carbon black. They have improved weather and UV radiation resistance and are more suitable for outdoor applications ISO 4892 (1.000 h) | |

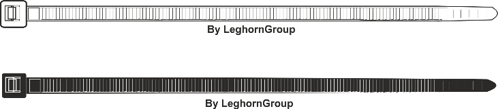

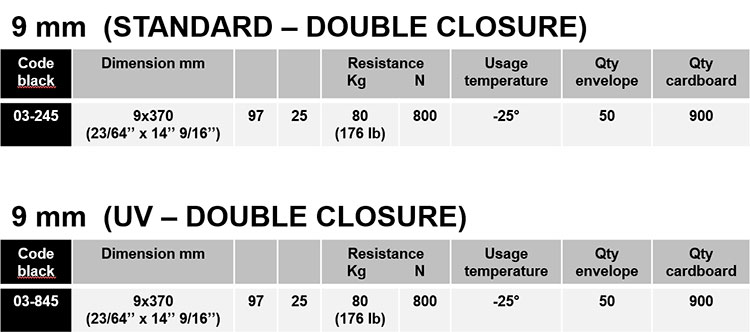

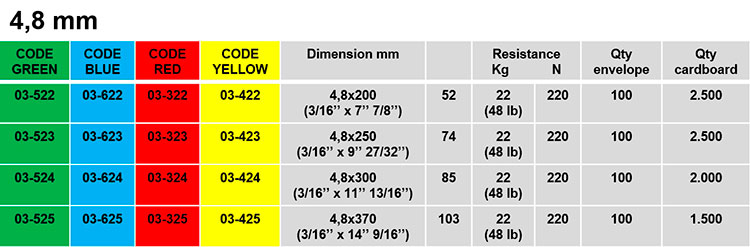

Cable ties STANDARD Poliammide Pa 6.6

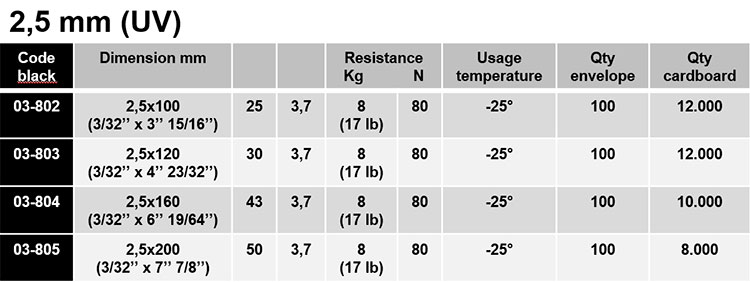

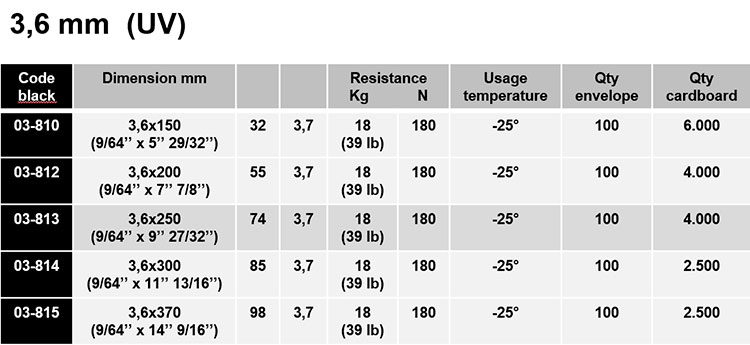

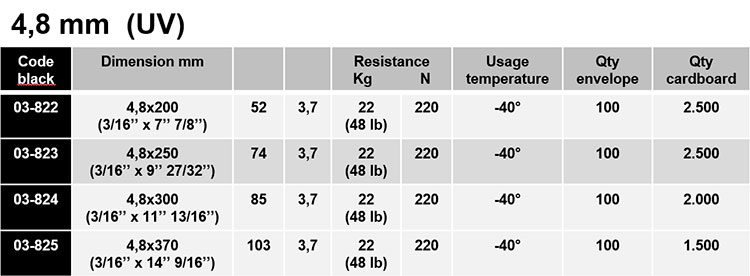

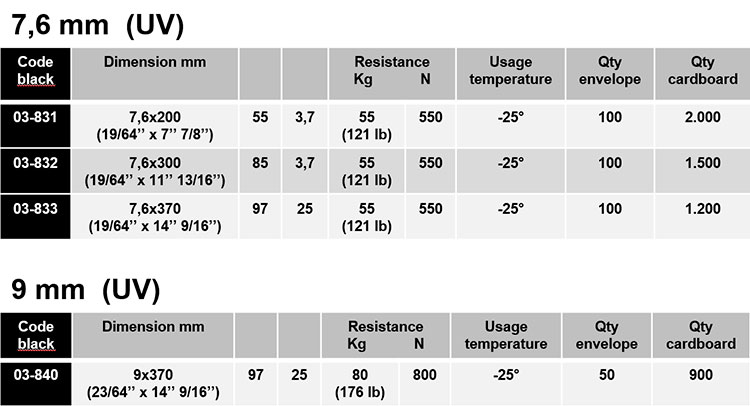

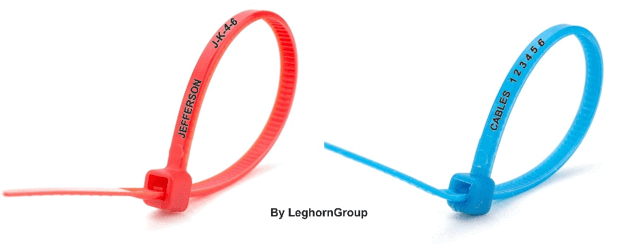

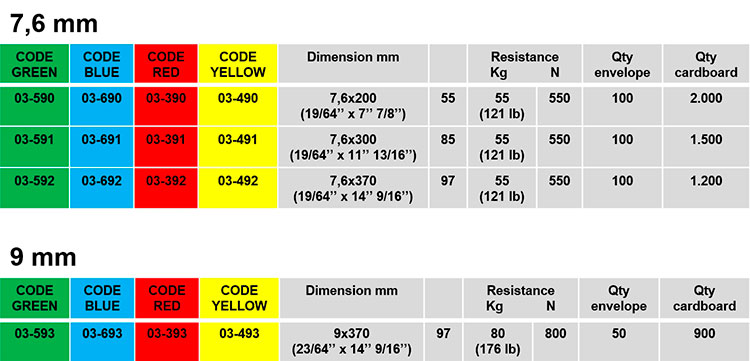

Cable ties UV Polyamide Pa 6.6

![]()

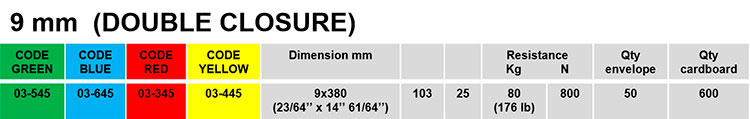

Cable ties Polyamide Pa 6.6 DOUBLE CLOSURE

![]()

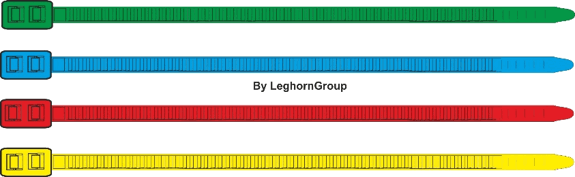

Cable ties Polyamide Pa 6.6 DOUBLE COLORED CLOSURE

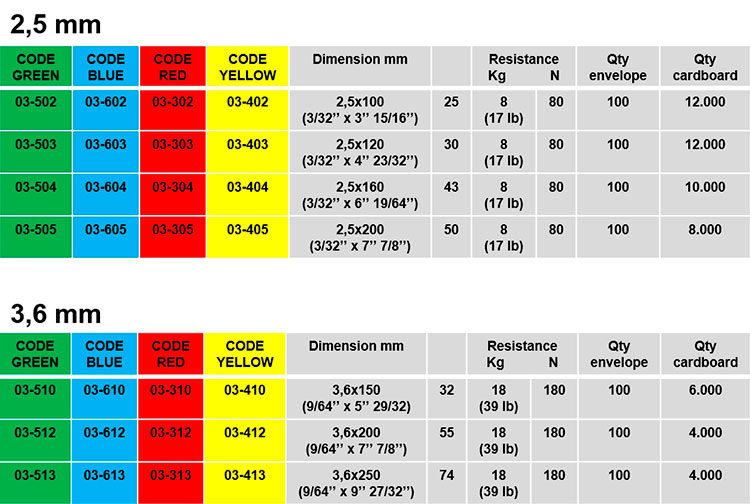

Cable ties COLORED STANDARDS Polyamide Pa 6.6

Cable ties COLORED STANDARDS Polyamide Pa 6.6

NUMBERED AND CUSTOMIZED UP TO 15 CHARACTERS

Creation of prototype and plastic moulding

Within 48 hours, we can prepare a three-dimensional draft that once approved turns into a 3D prototype that will be under your evaluation.

If you approve it, within 30-40 days we take your order under production and we will supply the first 1000 pieces for final tests.

Our team of experts in plastic moulding will surely meet your requirements.

Examples of use

You may also like…

-

Reusable cable ties

Reusable cable ties

-

Seal for fire extinguishers Arachne Seal

Beaded cable tie

-

RATTENSTAART

Reusable plastic fasteners