Description

CONTAINER MARKINGS

With billions of containers in circulation in world (approx 200 million TEU), the main issue of those who must transport them is knowing how to locate their container and or course the goods that are being transported.

ISO “International Organization for Standardization ” has established a unique identification code for every single container.

This alphanumerical code has 11 figures and is known as the “CODICE BIC” by the “BUREAU INTERNATIONAL DES CONTAINERS” Paris.

EXAMPLE

![[cml_media_alt id='2383']tagete_3[/cml_media_alt]](https://leghorngroup.com/wp-content/uploads/2014/12/tagete_3.jpg) From the code we can identify:

From the code we can identify:

The PROPRIETER

The CONTAINER NUMBER

A CHECK DIGIT

TTNU 302512 4

The proprietor: 4 letters

[fourth position: U,J,Z for worldwide traffic]

Service number(6 digits, proprietors choice)

+ Check digit number.

![[cml_media_alt id='2384']tagete_4[/cml_media_alt]](https://leghorngroup.com/wp-content/uploads/2014/12/tagete_4.jpg) The owner code, also known as Alpha Prefix, is only be issued for the whole world by BIC, while the service number is determined independently by the owner and the self-checking digit is automatically calculated by an algorithm starting from the previous ten letters and numbers.

The owner code, also known as Alpha Prefix, is only be issued for the whole world by BIC, while the service number is determined independently by the owner and the self-checking digit is automatically calculated by an algorithm starting from the previous ten letters and numbers.

The marking system of each container is normally performed using the letters and numbers, from the self adhesive plastic material that are applied on each side of the container to make sure it can be visually identified.

The control of each individual container is done visually by a human being that brings it back manually on the relevant documents.

A REGULARIZED CONTAINER, CAN HELP REGULARIZE OTHERSI

This is the control system largely used for checking containers: but it has serious deficiencies: Mainly the possibility of duplicating the same code on the self adhesive labels and applying it to more than one container.

As a result, as if by magic, an inspected and regularized container, automatically checks other containers “Homonyms” uninspected and therefore illegal.

The danger to the State and economical nature (is millions of dollars for every single container) also relative to the security (dangerous goods, arms explosives, chemical or biological hazards).

HUMAN ERROR

![[cml_media_alt id='2389']tagete_7[/cml_media_alt]](https://leghorngroup.com/wp-content/uploads/2014/12/tagete_7.jpg) Human error when reading the container ID and documents is around 12%.

Human error when reading the container ID and documents is around 12%.

Even if the error in unintentional, the economical damage is still thousands of dollars for the parties involved – both private companies and the Customs who handle the inspections. The time required to read the ID code, write it down on the relative document and then check this is lengthy.

![[cml_media_alt id='2388']tagete_8[/cml_media_alt]](https://leghorngroup.com/wp-content/uploads/2014/12/tagete_8.jpg) … The time taken has been calculated at between one to three minutes for each single container, which, if multiplied by hundreds of thousands of containers handled each year, gives an impressive figure of working hours that are used up to identify a container. The cost is millions of dollars.

… The time taken has been calculated at between one to three minutes for each single container, which, if multiplied by hundreds of thousands of containers handled each year, gives an impressive figure of working hours that are used up to identify a container. The cost is millions of dollars.

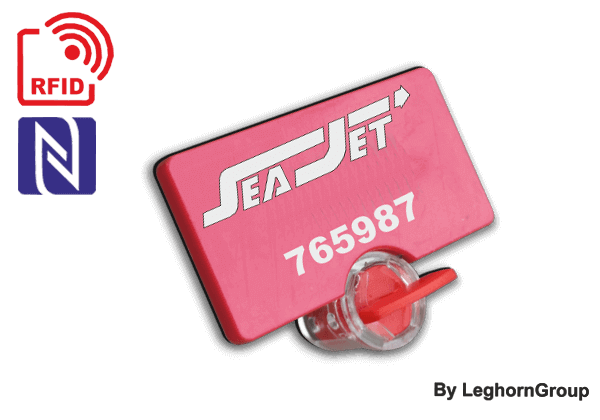

ALL THIS CAN COME TO AN END IMMEDIATELY using an RFID tag which visually states the number and identification code of the container, but CANNOT BE MODIFIED ON AN ELECTRONIC LEVEL .

RFID stands for “Radio-Frequency Identification”

RFID ELECTRONIC IDENTIFICATION

Easy to apply RFID plaque “TAGETE ” can be immediately used in any terminal equipped with doors with RFID readers and interfaces directly with any management system.

It can be read from several meters away and reduces human error to zero.

The placque is also fitted with a unique serial number and a user memory that can store info and data according to the requirement.

The RFID tags within our

“TAGETE*”

CONTAINER RFID E-LABEL are of the ISO standard : ISOIEC 18000-6C EPC CLASS1 GEN 2.

MADE IN ITALY

![[cml_media_alt id='2394']tagete_13[/cml_media_alt]](https://leghorngroup.com/wp-content/uploads/2014/12/tagete_13.jpg) The TAG RFID is uniquely numbered, cannot be modified in any way as the numbering is burned onto the chip’s memory.

The TAG RFID is uniquely numbered, cannot be modified in any way as the numbering is burned onto the chip’s memory.

This numbering on the chip is in turn linked to the container ID number, and together they ensure the identification of the container which can by no means repeated or copied.

![[cml_media_alt id='2395']tagete_14[/cml_media_alt]](https://leghorngroup.com/wp-content/uploads/2014/12/tagete_14.jpg)

The RFID tag can store the following basic information:

- Movement date

- Type of operation

- User who carried out the operation

- Container number

- Possible to add a further security code

The advantages of this model help raise productivity rate of container ![[cml_media_alt id='2396']tagete_15[/cml_media_alt]](https://leghorngroup.com/wp-content/uploads/2014/12/tagete_15.jpg) identification and container entrance/exit within the port.

identification and container entrance/exit within the port.

Furthermore, as it is unique, the RFID tag cannot be duplicated electronically, thus the history of the container movement is available for any kind of security check.

Our patented product (TAGETE*) can offer the above functions, without compromising the working order of an RFID seal in the event that it too is applied to the container.

Together, these RFID seals, provide an electronic control of the container that offers a level of security yet to be surpassed.

|

TECHNICAL SPECIFICATION TAGETE |

||

| Size | 216 x 315 mm | |

| Material | PVC | |

| Operating temperature | -40° a +70° | |

| Operating frequency | 860 – 960 MHz | |

| Protocoll | UHF – EPC Class 1 GEN 2 Compliant | |

| Total memory | 512 bit | |

| Tag function | Read/write | |

| Reading distance | Max 15 m (recommended) | |

TECHICAL DATA OF THE READER

EPR FAST LANE

– Operating frequency: 865-869 MHz, ETSI EN 302-208

– Protocol: ISO 18000-6C; EPC Class1 Gen2;

– Antenna: Special Embededd antenna system;

– RF Power: Programmable via software +32.5 dBm (fino a +30dBm se utilizzo di POE)

– Reader power supply: POE IEEE802.3 o 24 Vdc, 0,8A tramite alimentatore esterno;

– Alimentazione di rete: 100-240 Vac, 50/60Hz

– Communication port: Ethernet 10/100 Base-T Ethernet (RJ45);

– Sensors: for trigger signal

– Address Configuration: DHCP, Static, LLA + mDNS

– Enviromental Conditions:

– Operating Temperature: -20°C + 50°C

– Storage Temperature: -20 °C +60°C

– Size for base module: 350 x 560 x 270 mm

– Weight: 4000 g

– Certification: CE (FCC can also be supplied)

– Housing: Alluminio anodizzato & Polietilene

– Protezione IP: IP55

Optional Kits

Kit TEMP: kit operating temperature from – 40°C a + 75°C

Kit LED Alert: kit for led alarm and buzzer

Kit I/O interface: kit for signel interfacing I/O with external devices

MOBILE READER EPR GUN

![[cml_media_alt id='2398']tagete_17[/cml_media_alt]](https://leghorngroup.com/wp-content/uploads/2014/12/tagete_17.jpg)

– Product: EPR UHF GUN

– Dimensions: 146 x 74 x 126 mm

– Weight: 330g – 550g (depending on options)

– Processor/Memory: Marvel pX A270 520 MHz – Marvel PX A320 820 MHz (option) – 128 MB RAM/256MB ROM

– Operating system: Windows CE 5.0.

– Display: 3.5 TFT LCD256K color LCD QVGA resolution (240Wx320L) with backlight

– Battery performance: 3000 mAh Lithium Polymer main Battery Pack for PDA

4400 mAh Lithium Polymer main Battery Pack for UHF unit 100 mAh Lithium Polymer Back-up Battery

– Interface: Keyboard buttons and Touch screen, numeric key Hands free Speaker, Microphone/Receiver Headset Port

– Environment: -20°C ….. 50° C – 1.5 meters to polished concrete – IP54 sealing

– Standard communications: USB 1.1 Bluetooth WLAN 802 11b/g

– Optional communications: CDMA EVDO or 2000 1X GSM/GPRS/EDGE, WCDMA

– Exposition Slot: 1 Micro SD Slot. 1 SIM Slot

– RFID Unit: UHF- ISO 18000-6 C (866-954MHz)

– Options: 1D Laser Scanner or 2D Barcode Imager – 1.3 Megapixel fixed focus camera with flash – GPS Receiver

Single Slot Cradle – 4 Slot Cradle – Vehicle Cradle

CARACHTERISTICS

– Supports ISO18000-6 C (inc. C1G2)

– 2m+ of reading distance

– small/ light/ easy to use

– Windows CE 5.0

– USB + Bluetooth + WiFi

– Touchscreen

– Battery 3000 + 4400mAh (long life)

– CE approved

– IP54

You may also like…

-

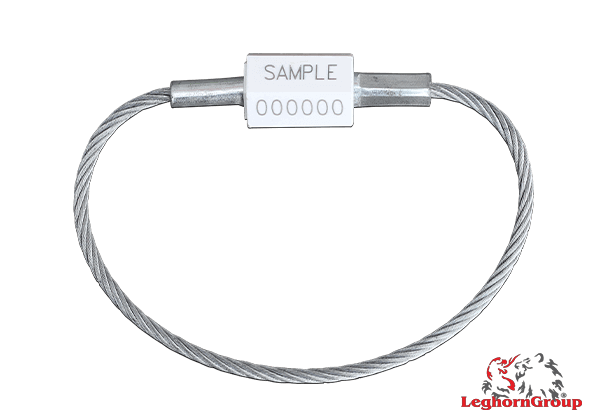

RFID seals for the management and traceability of industrial sludge bags

RFID e-seals suitable for identification, safety and tracing of industrial sludge bags

-

UHF/HF/NFC RFID meter seal TWIST SEAL

Wire seal available in UHF, HF and NFC operative frequency bands. Outer body and rotor made in plastics (PC and POM) having high mechanical resistance

-

Bolt lock UHF RFID three-state e-seal SOTER SEAL

UHF RFID bolt-lock seal, it can provide its status information, UNLOCKED, LOCKED or TAMPERED, which is stored in the RFID chip. Compliant with ISO 17712:2013

![[cml_media_alt id='2401']tagete_52[/cml_media_alt]](https://leghorngroup.com/wp-content/uploads/2014/12/tagete_52.jpg)

![[cml_media_alt id='2393']tagete_12[/cml_media_alt]](https://leghorngroup.com/wp-content/uploads/2014/12/tagete_12.jpg)